Home > Products > Rotary Kiln Equipment > Zinc oxide calcination kiln manufacturer in China

Zinc oxide calcination kiln manufacturer in China

- Qingdao

- T/T Credit Card

You May Like

-

Bauxite roasting furnace for ceramic proppant

-

limestone roasting furnace of limestone rotary kiln for industrial lime and lime powder

-

Zinc oxide production equipment for zinc ash and crude zinc oxide

-

kaolin rotary kiln for calcining kaolin clay price in China

-

High efficient Rotary Kiln with ISO CE approved

-

Rotary drum kiln structure

Product Details

| Condition | New | Production Capacity | 6.0-7.2t/h | |

| Place of Origin | Henan, China | Brand Name | Derui | |

| Model Number | Y-2540 | Voltage | 380v/50hz | |

| Power(W) | 55kw | Dimension(L*W*H) | 2.5*40m | |

| Weight | 139t | Certification | ISO,CE | |

| Warranty | one year | After-sales Service Provided | Engineers available to service machinery overseas |

Product Description

Zinc oxide calcination kiln manufacturer in China

Introduction of zinc oxide:

Zinc oxide also called zinc white or zinc oxide powder, always dispersed in rubber and latex, it is reinforcing agent, active agent and

vulcanizing agent for natural rubber, synthetic rubber, it is also coloring agent and filler for white plastic materials.

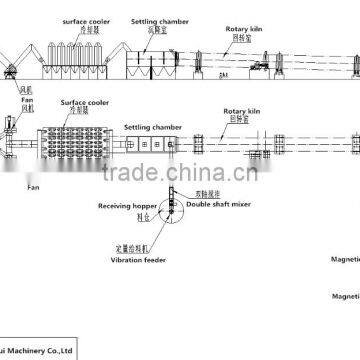

Zinc oxide calcination kiln production line:

First, crushing zinc furnace materials and coking coal into pallets less than 40 mesh, zinc furnace materials and coke mixed together

in proportion to 1:0.30-0.35.

Second, making the mixed materials into particle mixture, diameter is 8-15 mm and finally the mixed pellets enter into rotary kiln for

smelting.

Third, Zinc oxide ore or zinc-containing industrial slags(zinc-containing is 15%25%) calcining for producing zinc oxide, coke or coal can be saved significantly.

Fourth, zinc oxide obtained by smelting has advantages of high output, high quality, a small amount of nodulation.

Zinc oxide calcination kiln technical parameter:

| Model(m) | Diameter (m) | Length(m) | Slope(%) | Capacity(t/h) | Rotate Speed (r/min) | Motor Power(kw) | Weight(T) |

| φ1.4×33 | 1.4 | 33 | 3 | 0.9-1.3 | 0.39-3.96 | 18.5 | 47.5 |

| φ1.6×33 | 1.6 | 33 | 4 | 1.2-1.9 | 0.26-2.63 | 22 | 50 |

| φ1.6×36 | 1.6 | 36 | 4 | 1.2-1.9 | 0.26-2.63 | 22 | 52 |

| φ1.8×32 | 1.8 | 32 | 4 | 1.9-2.4 | 0.16-1.62 | 30 | 78.2 |

| φ1.8×45 | 1.8 | 45 | 4 | 2.8-3.34 | 0.21-2.11 | 30 | 95.2 |

| φ1.9×36 | 1.9 | 36 | 3.5 | 1.2-1.7 | 0.29-2.93 | 30 | 86.3 |

| φ1.9×45 | 1.9 | 45 | 3.5 | 1.65-2.5 | 0.29-2.93 | 37 | 109 |

| φ2.2×48 | 2.2 | 48 | 3 | 1.9-2.1 | 0.98-2.93 | 55 | 141 |

| φ2.5×40 | 2.5 | 40 | 3.5 | 6.0-7 | 0.44-2.44 | 55 | 139.61 |

| φ2.5×50 | 2.5 | 50 | 3.5 | 7.0-8.0 | 0.48-1.44 | 55 | 179.6 |

| φ2.5×54 | 2.5 | 54 | 3.5 | 8.0-8.6 | 0.48-1.44 | 55 | 196.29 |

| φ2.7×42 | 2.7 | 42 | 3.5 | 10.0-11.0 | 0.10-1.52 | 55 | 198.5 |

| φ2.8×44 | 2.8 | 44 | 3.5 | 11-12.5 | 0.80-2.39 | 55 | 198.6 |

| φ3.0×45 | 3 | 45 | 3.5 | 13.3-16.9 | 0.5-1.35 | 55 | 223 |

| φ3.2×52 | 3.2 | 52 | 3.5 | 16-18.5 | 0.48-2.44 | 110 | 278 |

During the EAF process, the high temperatures required to melt the feed material produce a zinc byproduct (EAF dust) that leaves the furnace along with the off-gases. The gases are filtered and the EAF dust is collected in bag houses.

The EAF dust waste steam is considered a hazardous material due to the potential for the heavy metals to leach into the ground, contaminating ground water and sewage systems.

The EAF dust generated by steel mills can be recycled in an economically viable way using the Waelz Kiln technology. The recycling process is part of the larger steel industry loop that allows the reuse of two important natural resources - zinc and iron.

Waelz Zinc Oxide is the main product of recycling EAF dust utilizing the Waelz Kiln technology. This product is sold to zinc smelters as an alternative to traditional zinc concentrates from mines. The zinc smelters produce pure zinc ingots or other high purity zinc products that are either sold to the steel industry for galvanization purposes or sold to other end-users for pigments, tires, chemicals or medicines.

(1) EAF steel dust is transported by road or rail to a steel dust recycling plant.

(2)The feed materials are provided in either dry compact-moist or pelletized form. The compact and pelletized moist materials, coarse fluxes and coke are stored in boxes while the dry dust is transported by pneumatic conveying systems to raw material silos.

(3)Typically 55 meters long with a four-meter diameter, the Waelz Kiln is slightly inclined 2-3% and has an approximate rotary speed of 1.0 rpm. As the moist material moves through the rotary kiln, it is dried and preheated by the kiln gas, flowing in a counter-current pattern. In the reaction zone, reduction of the metal oxides occurs around 1200°C as the zinc is vaporized as metal vapor into the gas cleaning system. Zinc is then re-oxidized in the kiln atmosphere that is operated with excess air (process air is injected from the kiln end). Chlorine and alkalis volatilize jointly with the heavy metals and the dust-laden off-gas is treated in a downstream off-gas system.

(4B)In the first stage, coarse particles mechanically entrained are separated in a dust settling chamber and returned to the kiln. The hot, dust-laden off-gas is cooled and Waelz Zinc Oxide is separated in a high efficiency collector.

(4A) The co-product, Waelz Iron Product, can be used directly in road construction, civil construction (backfilling), cement manufacturing or can be reprocessed to add more value to the iron content which is currently under research and development.

(5)The dust-free off-gas is then treated, filtered and discharged.

(6) The discharged air easily meets strict environmental regulatory standards

(7) Waelz Zinc Oxide, the main product of the process, is delivered to zinc smelters for zinc production.

Application of zinc oxide:

1. After adding the zinc oxide into rubber, it can make the rubber have excellent wear-resisting, tear-resisting and flexibility.

2. As a kind of white dyestuff, because of the active zinc oxide has excellent activation performance, it has been utilized more and

more widely in rubber products. For example, in the V type belt, it can not only take the place of common zinc oxide and it can

reduce more than a half to one third of the using quantity which can make various performance and index of the rubber stable and make curing properties not be influenced so as to reduce the cost.

3. The fine grained zinc oxide can be used as medicine.

4. Due to the strong ability of absorbing the ultraviolet rays, more and more people use it to color the paint, printing ink and varnished cloth.

5. The zinc oxide also can be used to fields like press -sensitive, photocatalysis, photoelectrode, paint, and color developing areas, etc.

Zinc oxide calcination kiln application:

Zinc oxide calcination kiln is a key equipment for treatment of Zn from Zinc smelters or steel mill dust, EAF dust, low grade zinc ore etc.

If you are interested in our Zinc oxide calcination kiln, pls kindly inform us the following info:

1. what is the raw material that you are going to process?

2. what is the capacity?

3. what is the feeding size of raw material?

4. what is your heat source?

Contact Us

- Gongyi Derui Machinery Co., Ltd.

- Contact nameLisa liu Chat Now

- Phone0086-371-64319887

- AddressMiddle of Heluo Road, Gongyi, Henan, China(Mainland), Zhengzhou, Henan

Product Categories

New Products

-

Iron ore reduction machine for iron oxide production line

-

kaolinite calcining kiln for kaolin clay price in China

-

EAF dust zinc oxide equipment for zinc ash recovery

-

Limestone burning kiln of limestone calcination kiln for active lime

-

Active lime rotary kiln for quick lime production line price in China

-

Iron ore calcination kiln for iron oxide production line price in China

-

EAF dust zinc oxide equipment for eaf dust recycling

-

bauxite ceramsite sand production equipment for bauxite and clay roasting

-

Zinc oxide production equipment for zinc oxide manufacturing plant

-

kaolin powder rotary kiln of kaolinite rotary kiln for kaolin clay calcined

-

Kaolinite rotary kiln for kaolinite clay calcined

-

kaolinite calcining kiln

-

Bauxite calcination equipment for bauxite powder

-

Limestone calcination kiln manufacturer

-

Iron ore reduction machine, iron ore calcination equipment, iron ore rotary kiln

-

Gypsum calcination equipment

-

Iron ore reduction machine manufacturer

-

Lime manufacturing machine of limestone rotary kiln price in China

-

Iron ore roasting kiln of iron oxide rotary kiln price in China

-

LECA Lightweight Expanded Clay Aggregate Rotary Kiln

-

Widely Used LECA Rotary Kiln with Energy Saving

-

China Low Price Lab Test Rotary Kiln

-

Hot Selling High Efficient Durable Kaolin and Metakaolin Rotary Kiln

-

2.5x40m Metallurgy Ilmenite Rotary Kiln Made in China

Popular Searches

- concrete truck

- active lime kiln

- lime kiln equipment

- industrial lime kiln

- shaft lime kiln

- vertical lime kiln

- rotary kiln

- cement grinding station

- mixer truck

- Concrete Mixer Truck

- Rotary Kiln Machine

- lime kiln

- kiln

- Lime Rotary Kiln

- Vertical Shaft Lime Kiln

- rotary kiln activated carbon

- cement kiln

- Cement Mixer Truck

- Mixer Tank Truck

- Mixer Machine Truck

- concrete mixer truck weight

- Concrete Mixer Car

- Vertical Shaft Kiln

- Quicklime Production Line

- Quicklime Rotary Kiln

- transit mixer

- mixer vehicle

- Clinker Grinding Plant

- cement truck

- wall paint spray gun

Recommended Products

- Water conservancy engineering mixing rod, concrete vibrator, excavator used

- Construction machinery concrete mixer hydraulic vibrator

- Engineering excavator modified vibrating rod concrete vibrating machine

- Concrete vibrating machine excavator modified vibrating rod

- Vibration compaction machine excavator modification z'd'qi

- Construction of concrete mixer, mechanical sliding mixing bucket

- Slip front mixer forklift modification mixing bucket discount

- Slip front mixer forklift modification mixing bucket discount

- Small shovel to mixer head loader hydraulic mixing bucket manufacturer

- Loader modification, mixing bucket manufacturer, concrete mixing machinery

- Excavator Concrete Vibrator Excavator Hydraulic Vibrator Bunker Vibrating Truck

- Hydraulic vibration compaction Excavator Concrete Vibrator

Find Similar Products By Category

- Manufacturing & Processing Machinery > Engineering & Construction Machinery > Concrete Machinery

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Lisa liu

Hi there! Welcome to my shop. Let me know if you have any questions.

Lisa liu

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile